What is a Tetra Pak made from?

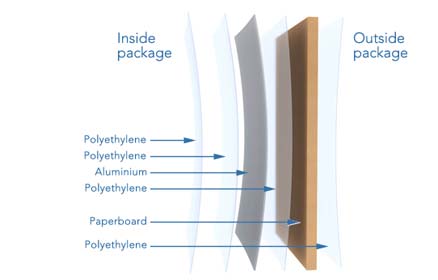

Tetra Paks are made up of a number of components which are layered: paperboard (made from wood), polyethylene (a type of plastic) and aluminum. These different components give Tetra Paks their unique properties: keeping the liquids in but the microbes out, and a strong but lightweight container.

When a Tetra Pak is recycled, all these component parts need to be separated out.

What Does Recycling Mean?

Whilst recycling can be thought of as a way of converting waste into a new material, more accurately it means a process to return material to a previous stage in a process that operates as a cycle. After all, the word is “re-cycling”. The idea is to take a used product and turn them back into the same type of product, such as glass bottles being melted down and formed into new glass bottles. There is no loss of quality, so this recycling of glass can go on forever.

When a product doesn’t get turned back into the same product, but one of lesser quality (as with plastic recycling) it isn’t recycled, it’s downcycled. Products that are downcycled often only undergo a limited number of cycles (maybe as few as 2) before reaching the end of their useful lives and ending up in landfill.

For Tetra Pak to be truly recycled, these layers of paperboard, polyethylene and aluminium would need to be separated out, and reformed to make new Tetra Pak cartons. However, that isn’t what happens.

Why Tetra Paks aren’t Sustainable

If Tetra Paks are recyclable, why aren’t they green? Let’s look at the different components, where they come from and what happens to them once the cartons are empty.

Paperboard (Wood)

Tetra Pak have devoted a significant amount of their website space to telling customers how sustainable their containers are. As well as talking at length about Tetra Paks being recyclable, they inform us that Tetra Pak source FSC-certified wood for 41% of their cartons worldwide (2013 figure). This equated to 32 billion FSC-labelled Tetra Paks reaching consumers in 2013.

Let’s look at this another way.

If 32 billion containers is 41%, then the amount of non-FSC wood Tetra Paks reaching consumers would be 46 million. 46 million containers made from non-renewable sources? That is a lot of wood. Tetra Pak might have a goal to reach 100% FSC-wood, but it isn’t happening now.

When this paperboard is recycled, it isn’t turned back into new Tetra Paks. It is unclear whether this is because their paperboard needs to come from virgin sources to avoid contamination (as is the case with plastic), or whether the quality of the recycled paperboard isn’t high enough to make new cartons, or some other reason. Whatever the reason, it is turned into office paper.

Plastic and Aluminium

The other two layers of the Tetra Pak, polyethylene (plastic) and aluminium, cannot be separated by the recycling process and remain combined as a “polymer”. The uses for this “polymer” is in the cement industry, or as low-cost housing material. The question arises, is there a genuine demand for this product, or is there a market because of an abundant supply of this waste material?

The fact that it gets reused and isn’t sent to landfill is great, except it doesn’t serve to make Tetra Paks a “green” solution. These cartons use fresh plastic and aluminium to make their cartons, and the waste products becomes something else entirely. Thus it is a linear system, not a cycle – and anything that is linear cannot be sustainable long-term.

A Word on Recycling Tetra Paks

The other thing to alwyas remember about recycling, is just because something can be recycled, it doesn’t mean that it will be recycled. The two are very different.

The Conclusion

Tetra Pak may want to be sustainable; they may want to use 100% FSC wood and achieve 100% recycling rates, but they still have a long way to go. Even if they achieve this, there’s no getting away from the fact that Tetra Pak production is a linear process. Tetra Paks are turned into different post-consumer products, meaning a constant supply of fresh virgin material (wood, oil and aluminum) is needed for their manufacture.

So after we drop our empty Tetra paks into the yellow container, they do go to a recycling plant but are not made into new Tetra paks but something else. That is a huge problem because there are a lot of products in Tetra pak containers but finding alternatives is not too difficult.

The blog song for today is : "Perfect Day" by Lou Reed

TTFN

No comments:

Post a Comment